ACRYLIC FABRICATION

ACRYLIC FABRICATION and award winning print production under one roof. An unbeatable combination!

Acrylic Fabrication solutions for businesses across the UK!

Daytona Visual offer comprehensive acrylic fabrication solutions to businesses across the UK and beyond, allowing you to bring all your print and fabrication production requirements under one roof.

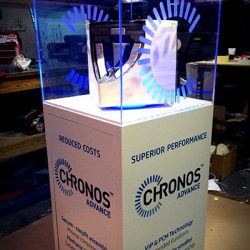

By combining industry leading direct to substrate, large format print technology, with our in-house acrylic fabrication skillset and equipment, Daytona Visual has become an important trade partner for many companies. Whatever sector you are in, we can find a high quality acrylic fabrication solution.

- Exhibition contractors

- Stand builders

- Retailers

- Event, leisure & hospitality

- Brands

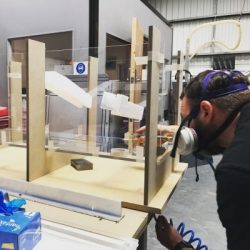

Full in-house production from start to finish.

All aspects of production are kept in-house, keeping costs competitive whilst maintaining maximum quality control.

We use a combination of high definition flat bed print technologies, materials, flexible inks, bonding and fabrication techniques and processes. This results in a professional quality finish on all your Acrylic Fabrication requirements.

Fabrication Techniques

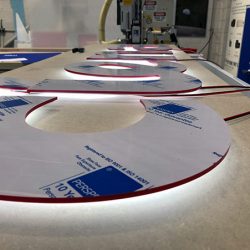

With the latest direct to substrate print technology combined with specially developed flexible inks, Daytona Visual know how to print onto and then work with the many different and often challenging acrylic substrates required to create visually stunning displays.

At Daytona Visual we work with all kinds of acrylic including cast acrylic, extruded acrylic, frosted acrylic and many more.

Our state-of-the-art acrylic fabrication technologies and skill set keeps all aspects of fabrication in-house, keeping costs down and maintaining best economy for our customers.

In-house services include:

- ACRYLIC & PERSPEX CNC MACHINING

- COLD LED UV ACRYLIC PRINTING

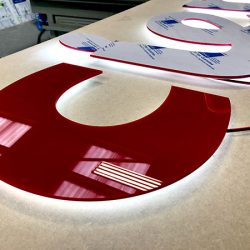

- SUPERIOR PRINT QUALITY

- ACRYLIC HEAT & LINE BENDING

- QUICK TURNAROUND

- EXHIBITION GRAPHICS

- ACRYLIC LETTERING

- LED ILLUMINATED ACRYLIC LETTERING

- FLAME POLISHING

- DIAMOND EDGE POLISHING

- ACRYLIC DISPLAY FABRICATION

Let’s make it happen!

Send us your Acrylic Fabrication enquiry below, and we’ll get the ball rolling.

About using Acrylic for display fabrication.

Acrylic, also known as Poly(methyl methacrylate) (PMMA), is a transparent thermoplastic. Brand names include “Perspex” and “plexiglass”, however there are also other good manufacturers with similar offerings and knowing what to use can be an important factor for economical display production.

Acrylic sheet is normally manufactured in two differing processes called ‘cast’ or ‘extruded’. Cast acrylic is normally regarded as better quality. The production methods have subtle but potentially significant differences, depending on the required use or method of machining. Acrylic is available in sheet and round (tubular) stock. This makes Acrylic a popular choice for CNC and other subtractive machining processes and a great material for producing attractive point-of-sale and display units.

An advantage of using Acrylic for display fabrication is that a very strong clear bond can be created using solvents such as trichloromethane. This dissolves the joint where the two plastic edges meet. In turn this forms a clear and sometimes invisible bond or ‘weld’, for a professional ‘high-end’ finish. Scratches can easily be removed by polishing and flame polishing. Acrylic is machined using our CNC routing technology and laser cutting where required.

Environmental safety.

While the related plastic known as Polycarbonate contains Bisphenol A (BPA), Acrylic does not contain BPA and therefor considered safe.